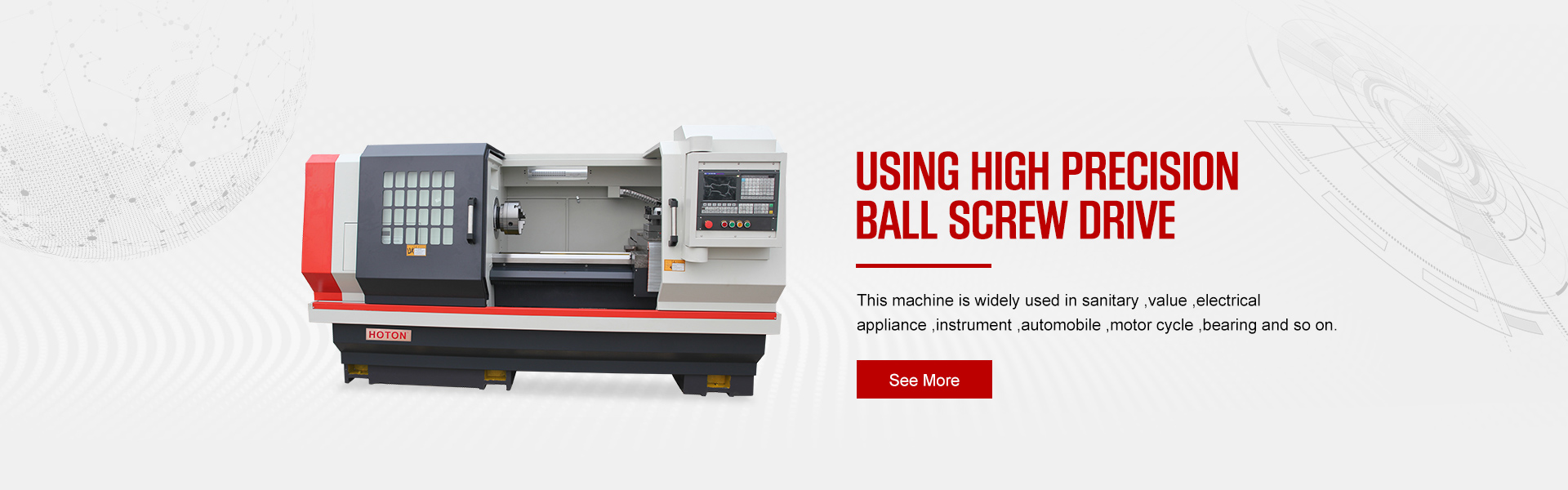

Short Lead Time for Machining Centre Mill 500 - CNC Slant Bed Lathe Machine TCK6340 – Hoton

Short Lead Time for Machining Centre Mill 500 - CNC Slant Bed Lathe Machine TCK6340 – Hoton Detail:

Application:

This machine is applicable to automobile, motorcycle, electronics, aerospace, military, oil and other industry. It could turn the conical surface, circular arc surface, end face of the rotary parts, could also turn various

metric and inch threads etc, with higher efficiency and higher precision in bulk.

The main performance characteristics:

1.45 degrees slant bed CNC lathe

2.Higher accuracy Taiwan linear

3.Chip conveying capacity is large and convenient, customer could choose chip conveying in the front or in the back

4.Screw pre-stretching structure

5.Gang type tool post

Standard Accessories

Fanuc Oi Mate-TD control system

Servo motor 3.7 kw

4 station gang type tool post

8" non thru-hole type hydraulic chuck

Optional Accessories

Main Motor: Servo5.5/7.5KW , Inverter 7.5KW

Turret: 4 station electric turret ,6 station electric turret

Chuck:6″Non-through hole hydraulic chuck ,8″Non-through hole hydraulic chuck (Taiwan)

8″through hole hydraulic chuck(Taiwan)

Chip conveyor

Steady Rest

Other optional item: Driving tool turret, automatic

feeding device and manipulator.

Product main technical parameters:

| Specification | Unit | TCK6340 | TCK6350 |

| Max. swing over bed | mm | 400 | Φ520 |

| Max. swing over cross slide | mm | 140 | Φ220 |

| Max. processing length | mm | 300 | 410( gang tool)/530 (turret) |

| X/Z axis travel | mm | 380/350 | 500/500 |

| Spindle unit | mm | 170 | 200 |

| Spindle nose | A2-5 | A2-6(A2-8 optional) | |

| Spindle bore | mm | 56 | 66 |

| Spindle drawing pipe diameter | mm | 45 | 55 |

| Spindle speed | rpm | 3500 | 3000 |

| Chuck size | inch | 6/8 | 10 |

| Spindle motor | kw | 5.5 | 7.5/11 |

| X/Z repeatability | mm | ±0.003 | ±0.003 |

| X/Z axis feed motor torque | N.m | 6/6 | 7.5/7.5 |

| X/Z rapid traverse | m/min | 18/18 | 18/18 |

| Tool post type | Gang type tool post | Gang type tool post | |

| Cutting tool shape size | mm | 20*20 | 25*25 |

| Guide form | 45° inclined guide rail | 45° inclined guide rail | |

| Total power capacity | kva | 9/11 | 14/18 |

| Machine dimension (L*W*H) | mm | 2300*1500*1750 | 2550*1400*1710 |

| N.W. | KG | 2500 | 2900 |

Product detail pictures:

Related Product Guide:

Singer Kate Bush career retrospective is overwhelmingly good | Cnc-Controlled Flatbed Lathe

Understanding Laser Cutting | Hydraulic Ring Bending Machine

We're going to commit ourselves to giving our esteemed buyers using the most enthusiastically considerate solutions for Short Lead Time for Machining Centre Mill 500 - CNC Slant Bed Lathe Machine TCK6340 – Hoton , The product will supply to all over the world, such as: Bahrain , Malawi , Bangladesh , The quality of our products is equal to OEM's quality, because our core parts are the same with OEM supplier. The above products have passed professional certification, and we not only can produce OEM-standard products but we also accept Customized Products order.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!