Welcome to our websites!

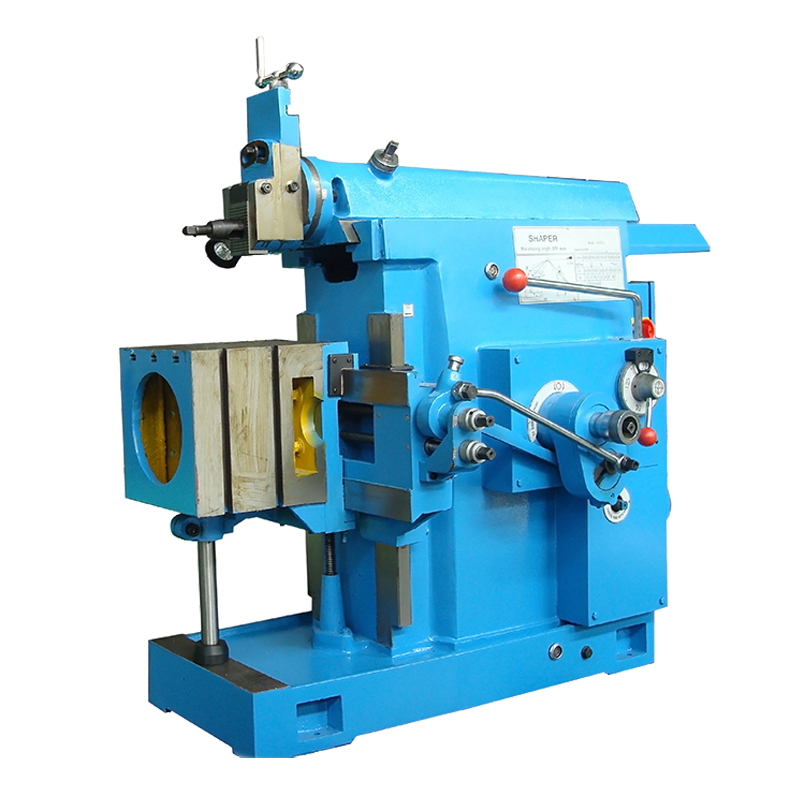

professional factory for Hydraulic Sectional Steel Shears - CNC Milling Machine Center XK7125 – Hoton

professional factory for Hydraulic Sectional Steel Shears - CNC Milling Machine Center XK7125 – Hoton Detail:

PRODUCT MAIN TECHNICAL SPECIFICATIONS:

1.mini cnc milling economic machine center XH7125 is with box guideways, ensuring the machine's machining accuracy and stability.

2.The small vmc machine can be with taiwan arm type tool magazine or drum type tool magazine with 10 tools capacity.

It can change tools quickly.

3.The machine is with RS232 interface, separated handwheel, spindle blowing chip removal system.

| SPECIFICATIONS | UNIT | XH7125 | XK7125 |

| Table size | mm | 900×250 | 900×250 |

| X-axis travel | mm | 450 | 450 |

| Y-axis travel | mm | 260 | 260 |

| Z-axis travel | mm | 380 | 380 |

| Distance from spindle axis to column surface | mm | 330 | 330 |

| Distance between spindle nose and worktable | mm | 50-430 | 50-430 |

| The vertical tolerance of distance between spindle nose and worktable | mm | <=0.02 | <=0.02 |

| X/Y/Z rapid traverse | M/min | 6/5/4 | 6/5/4 |

| Max.spindle speed | rpm | 6000 | 6000 |

| Spindle taper | BT30 | BT30 | |

| Main motor power | kw | 2.2 | 2.2 |

| X axis motor torque | N.m | 7.7 | 7.7 |

| Y axis motor torque | N.m | 6 | 6 |

| Z axis motor torque | N.m | 6 | 6 |

| Tool capacity | 12 armless type tools magazine | - | |

| Positioning accuracy | mm | 0.02 | 0.02 |

| Repeat positioning accuracy | mm | 0.01 | 0.01 |

| Machine dimension | mm | 2200×1650×2200 | 1200×1500×2100 |

| Machine weight | kg | 1800 | 1400 |

Product detail pictures:

Related Product Guide:

How Chloe Kim Won Gold With a Nearly Perfect Score in Halfpipe | Shearing Machine

Interior work beginning at new Meadow View Elementary in Oconomowoc | Hydraulic Ring Bending Machine

It adheres on the tenet "Honest, industrious, enterprising, innovative" to acquire new solutions continuously. It regards prospects, success as its personal success. Let us build prosperous future hand in hand for professional factory for Hydraulic Sectional Steel Shears - CNC Milling Machine Center XK7125 – Hoton , The product will supply to all over the world, such as: Uzbekistan , Costa Rica , Gabon , Aiming to grow to be by far the most experienced supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal merchandise. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're about to make it possible for you to get complete acknowledge about our things and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.