OEM/ODM Supplier Turning And Boring Lathe - CNC Milling Machine XH7145A – Hoton

OEM/ODM Supplier Turning And Boring Lathe - CNC Milling Machine XH7145A – Hoton Detail:

LINEAR GUIDEWAY CNC MACHINING CENTER

1.This XH7145A CNC milling machine center of feed shaft controlled by X,Y,Z coordinate , spindle driven by Frequency motor.All kinds of plate, sheet, shell, cam, moulds and some other complicated parts' can realized holding by one time, more difference machining procedule such as drilling, milling, boring, expanding, tapping can be finished, applicable for more kinds, medium-small batch production,specially advanced in machining the complicated and high precision spare parts.

2.The CNC system has the function of interlock alarm, safety protection and fault diagnosis and has RS232 standard communication taeminals, can connected with computer for program control and memory, DNC production.

II. Main features

1. XH7145A Machine center's base, slide, worktable, column, spindle and other main parts applicated high rigid cast iron structure, guarantee the main parts' high rigid and anti-vibration. The main parts all adopted by resin sand and aging treatment, assuring the stability of the machine

2.X,Y, Z-axis adopted linear rolling guide rail, eliminating the feeding friction resistance and low speed creep, longer machine precision life.

III.Advantages

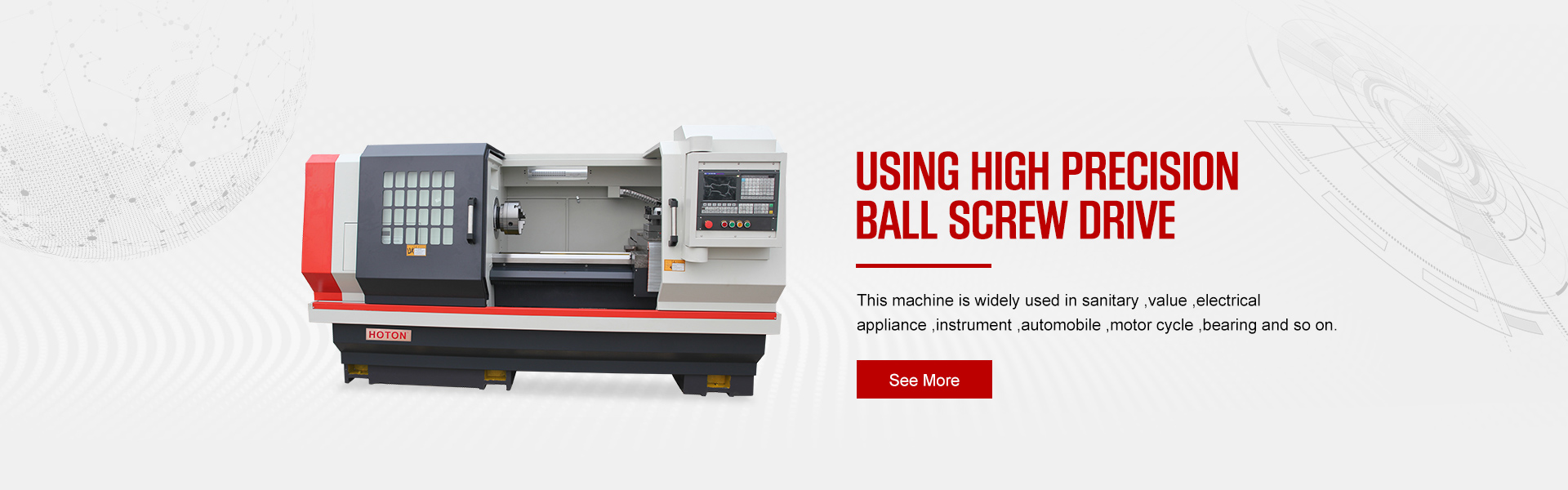

1..X, Y, Z-axis adopted famous brand high precision ball lead screw, resulted high rapid speed and high positional accuracy.

2.X, Y, Z-axis guide way and lead screws adopted full confined protection, assuring the cleaness of lead screw and guide way as well asmachine's transmission and motion precision.

3.The outside protection of the machine is full-closed structure, guarantee the safety. semi-closed protection is also available. .

4.XH7145A CNC milling machine center tool operation system by the principle of human body engineering design, easy operation.

5.XH7145A CNC milling machine center Manual central lubrication and high stability.

6.Famous CNC system, FANUC, KND, SIEMENS, MITSUBISHI for your choices.

| SPECIFICATION | UNIT | XHS7145 | XH7145A | XK7145A |

| X-axis travel | mm | 600 | 700 | 700 |

| Y- axis travel | mm | 450 | 450 | 450 |

| Z- axis travel | mm | 500 | 500 | 500 |

| Spindle nose to table | mm | 130-630 | 120-620 | 120-620 |

| Spindle center to column guide-way face | mm | 485 | 460 | 460 |

| High speed feeding of X,Y, axis | mm/min | 24000 | 12000 | 12000 |

| High speed feeding of Z axis | mm/min | 18000 | 10000 | 10000 |

| Feeding speed | mm/min | 1-5000 | 1-5000 | 1-5000 |

| Size of table | mm | 1000x450 | 1000x450 | 1000x450 |

| Max. loading capacity of table | kg | 600 | 600 | 600 |

| T-slot NO./width /distance of table | 3/18/160 | 5/18/80 | 5/18/80 | |

| Spindle max. speed | r/min | 8000 | 8000 | 8000 |

| Main motor rated power | kw | 5.5/7.5 | 5.5/7.5 | 5.5/7.5 |

| Spindle nose taper | BT40 | BT40 | BT40 | |

| ax. diameter of tools | mm | 80/130 | 80/130 | - |

| Max. length of tools | 300 | 300 | - | |

| Max. weight of tools | kg | 6 | 6 | 6 |

| Positioning accuracy | mm | 0.025(GB)0.016(Real) | 0.025(GB)0.016(Real) | 0.05(GB)0.02(Real) |

| Re-positioning accuracy | mm | 0.015(GB)0.008(Real) | 0.015(GB)0.01(Real) | 0.02(GB)0.012(Real) |

| Pneumatic press | mpa | 0.6 | 0.6 | 0.6 |

| N.W | kg | 3500 | 3500 | 3400 |

| Overall dimension | mm | 2500x2000x2450 | 2500x2000x2450 | 2500×2000×2450 |

Product detail pictures:

Related Product Guide:

17 Car Craft Approved Tools (And One Huge Turbo) Spotted at the 2016 SEMA Show #TENSEMA16 | Cnc-Controlled Flatbed Lathe

An oral history of the Makers, 25 years after their debut LP Howl | Sound Advice | Spokane | The Pacific Northwest Inlander | Metal Craft Pipe Bender

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for OEM/ODM Supplier Turning And Boring Lathe - CNC Milling Machine XH7145A – Hoton , The product will supply to all over the world, such as: Puerto Rico , Kyrgyzstan , Macedonia , We have now a good reputation for stable quality goods, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!