Factory source Forging Hammer C41-75 - Universal Lathe CD6240C – Hoton

Factory source Forging Hammer C41-75 - Universal Lathe CD6240C – Hoton Detail:

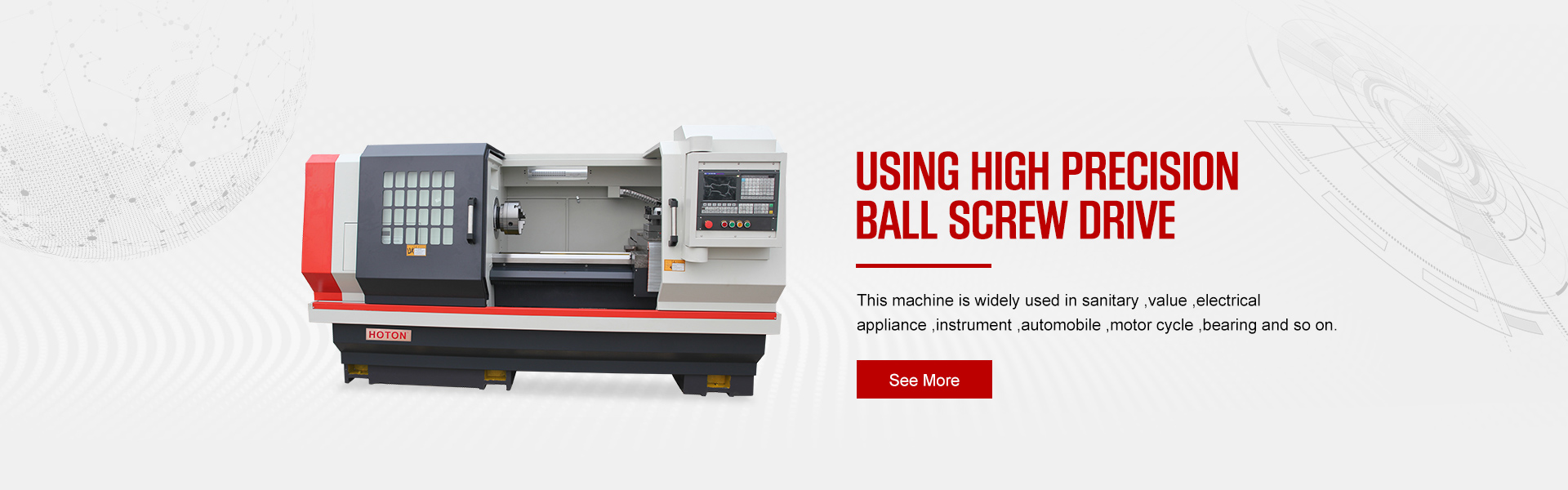

CDC Series Large Spindle Hole Precision Lathe

Over sized spindle bore of 80mm

Main spindle dynamic balanced, and supported at 2 points with taper roller bearing of Harbin brand.

Outward appearance of machine features large plains, making the machine more good-looking

Gapped bed ways, which are super-audio frequency hardened (HB450 plus).

All gears hardened and ground by Reishauer grinding machine.

Leadscrew and feed-rod interlocked, both with overload protection.

Automatic feed stopper.

Configuration variable totally according to orders:

Metric or inch system; Right or left hand wheel; Halogen lamp; Quick change; Tool post; DRP; T-slot compound; Chuck guard; Leadscrew hood; Rapid traverse motor; Electromagnetic brake; Forced lubrication system.

SPECIFICATIONS:

|

MODEL |

CD6240C |

CD6250C |

CD6260C |

|||

|

CAPACTIES |

Max. swing over bed mm |

400 |

500 |

600 |

||

|

Max. swing over cross slide mm |

225 |

325 |

360 |

|||

|

Max. swing in gap mm |

530 |

630 |

730 |

|||

|

Center distance |

1000,1500, 2000mm |

|||||

|

Cross slide travel mm |

330mm |

|||||

|

SPINDLE |

Spindle hole |

80mm |

||||

|

Spindle nose |

ISO-C8 or ISO-D8 |

|||||

|

Spindle taper |

Metric 85mm |

|||||

|

Spindle speeds |

24-1600rpm (15 Steps) |

|||||

|

FEEDS |

Metric threads range (Kinds) |

0.5-28mm (66Kinds) |

||||

|

Inch threads range (Kinds) |

1-56tpi (66 Kinds) |

|||||

|

Module threads range (Kinds) |

0.5-3.5mm (33 Kinds) |

|||||

|

Diametral threads range (Kinds) |

8-56 DP (33 Kinds) |

|||||

|

Longitudinal feeds range(kinds) |

0.072-4.038mm/reV (0.0027-0.15inch/rev)(66kinds) |

|||||

|

Cross feeds range (kinds) |

0.036-2.019mm/reV (0.0013-0.075nch/rev)(66kinds) |

|||||

|

Rapid traveling speed of carriage |

5m/min(16.4ft/min) |

|||||

|

Leadscrew size:Diameter pitch |

35mm/6mm or 35mm |

|||||

|

CARRIAGE |

Cross slide travel |

300mm |

||||

|

Compound rest travel |

130mm |

|||||

|

Cross-section size of tool shank |

25x25mm |

|||||

|

TAILSTOCK |

Spindle diameter |

65mm |

||||

|

Spindle taper |

Morse No. 5 |

|||||

|

Spindle travel |

120mm |

|||||

|

Main motor |

Main drive motor |

4.0kw or 5.5kw |

7.5kw |

|||

|

Coolant pump motor |

0.125kw |

|||||

|

Rapid traverse motor |

0.12kw |

|||||

|

Net weight/Gross weight(kg) |

1000mm |

1640/2290 |

1700/2350 |

1800/2500 |

||

|

1500mm |

1850/2250 |

1910/2610 |

2010/2760 |

|||

|

2000mm |

2090/2860 |

2150/2920 |

2250/3070 |

|||

|

PACKING SIZE |

1000mm |

2420*1150*1800mm |

||||

|

1500mm |

2920*1150*1800mm |

|||||

|

2000mm |

3460*1150*1800mm |

|||||

Product detail pictures:

Related Product Guide:

Specialist CNC machining solutions from JJ Smith | Shearing Machine

Interior work beginning at new Meadow View Elementary in Oconomowoc | Metal Craft Pipe Bender

Our primary objective is usually to offer our shoppers a serious and responsible small business relationship, offering personalized attention to all of them for Factory source Forging Hammer C41-75 - Universal Lathe CD6240C – Hoton , The product will supply to all over the world, such as: Vietnam , Maldives , Chile , Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!