Essential Tips for Choosing the Right Cylinder Boring Honing Machine

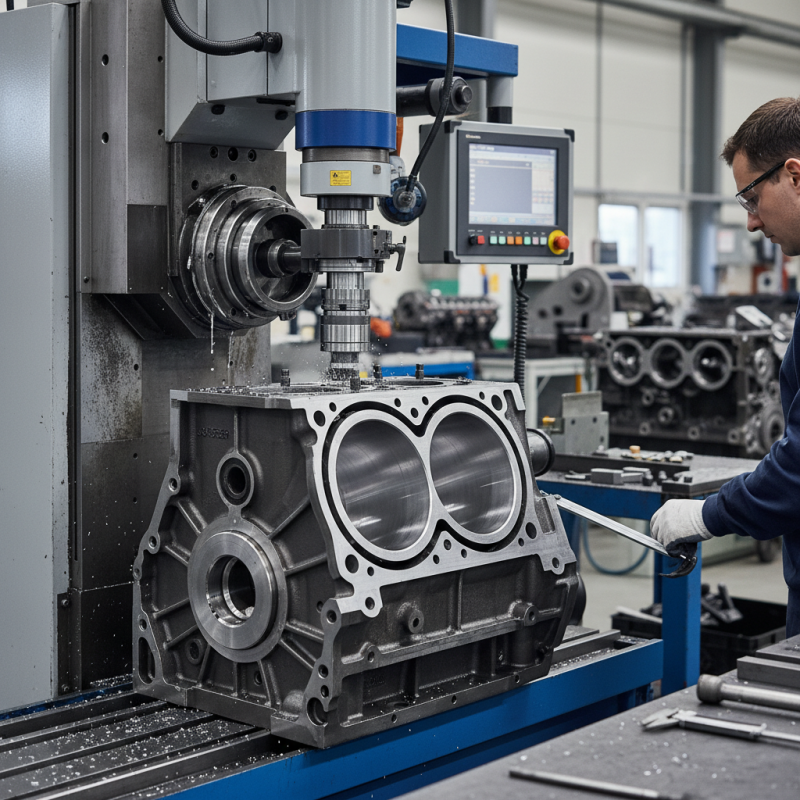

When it comes to enhancing the performance and longevity of engine components, a Cylinder Boring Honing Machine stands out as an indispensable tool in the automotive and mechanical engineering sectors. This specialized equipment is designed to create precise cylindrical holes in engine blocks, ensuring optimal alignment and fit for piston rings. Choosing the right machine, however, involves careful consideration of several key factors that can significantly impact the quality of workmanship and overall efficiency in your operations.

Firstly, the specifications and capabilities of the Cylinder Boring Honing Machine should align with your specific needs, including the size of the engine blocks you will be working with and the types of materials you commonly encounter. Additionally, it's essential to evaluate the machine's features, such as its automation level and ease of use, which can greatly affect productivity in your workshop. Understanding these elements will not only improve the performance of your projects but also help you make a more informed investment decision.

In conclusion, investing in the right Cylinder Boring Honing Machine can lead to significant advantages in both precision and efficiency. By taking into account key factors like specifications, features, and your operational requirements, you can select a machine that best suits your needs, ensuring high-quality results in your engine rebuilding processes.

Understanding Cylinder Boring and Honing Processes

Cylinder boring and honing are critical processes in the automotive and manufacturing industries, particularly for maintaining engine efficiency and performance. Cylinder boring involves creating a precise hole in the engine cylinder to accommodate a larger piston, while honing follows to enhance the surface finish and ensure optimal clearance. According to a report by Market Research Future, the global engine remanufacturing market is projected to grow significantly, driven by the increasing demand for high-performance engines and the popularity of eco-friendly vehicles. This underscores the importance of effective cylinder boring and honing processes in modern engine manufacturing.

The honing process uses abrasive stones to refine the cylinder walls, which has been shown to improve oil retention and reduce friction. A study from the International Journal of Engineering Research highlighted that precision honing can enhance engine durability by up to 15% on average, demonstrating the value of investing in high-quality honing machinery. Additionally, advancements in technology have led to the development of automated honing systems that improve accuracy and reduce cycle times, making it crucial for manufacturers to stay updated with industry trends and innovations to maintain competitive advantages.

Essential Tips for Choosing the Right Cylinder Boring Honing Machine

Key Features to Look for in a Boring Honing Machine

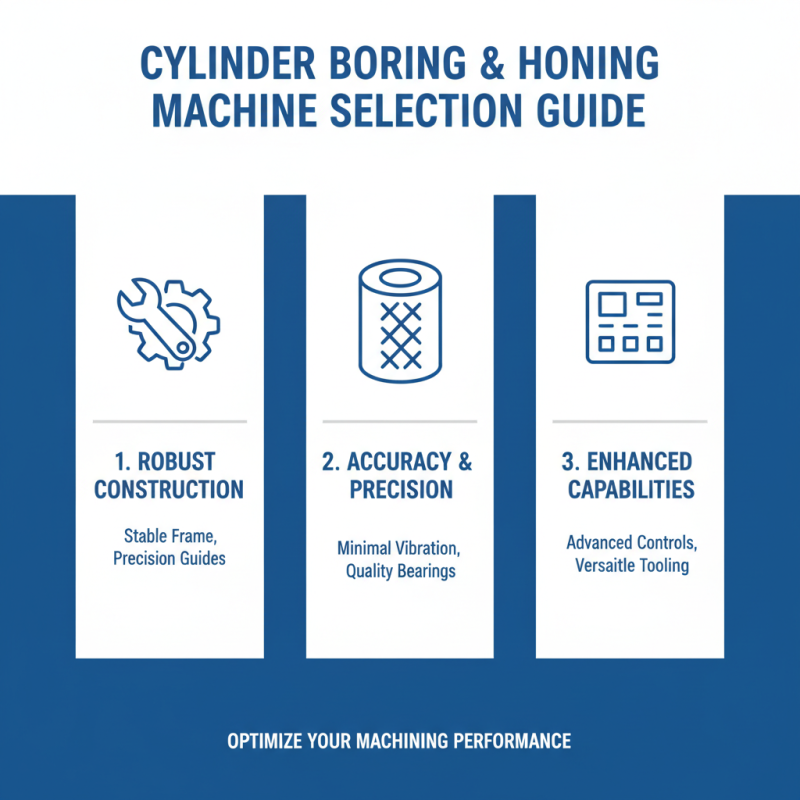

When selecting a cylinder boring honing machine, certain key features can significantly enhance your machining capabilities and overall performance. Firstly, consider the machine's construction and rigidity. A robust frame ensures stability during operation, which is crucial for achieving precise cylinder bore dimensions. The machine should also be equipped with high-quality guides and bearings that minimize vibrations, thus improving the accuracy of the honing process.

Another essential feature to evaluate is the machine's versatility. Look for models that can accommodate various cylinder sizes and are adaptable to different honing operations. This flexibility allows for greater efficiency, enabling you to handle a wider range of projects without investing in multiple machines. Additionally, the incorporation of advanced digital control systems can enhance ease of use and repeatability, ensuring consistent results across numerous cycles.

Lastly, consider the machine's maintenance requirements and operational efficiency. A design that facilitates easy access to crucial components for cleaning and servicing can save time and reduce downtime. Furthermore, ensuring that the machine has energy-efficient features can not only lower operational costs but also positively impact the environmental footprint of your machining practices. Choosing a machine with these key features will ultimately lead to more effective machining and better overall outcomes for your projects.

Evaluating Machine Size and Capacity for Your Needs

When selecting a cylinder boring honing machine, evaluating the machine size and capacity is crucial to ensure it meets your specific needs. First, consider the types of projects you will be working on. If your primary focus is on smaller engines or hobbyist projects, a compact machine may suffice. However, for larger applications or commercial use, investing in a larger machine with a higher capacity will enable you to handle bigger jobs more efficiently. Analyzing the size of the cylinder bores you plan to work with will help you determine the necessary specifications for your machine.

In addition to size, pay attention to the machine's capacity, which refers to its ability to handle various cylinder sizes and depths. Make sure the machine can accommodate the largest bore diameters you'll encounter while also providing flexibility for smaller tasks. It's also vital to consider the machine's stroke length and the ability to adjust settings for different materials and polishing techniques. This versatility can enhance your productivity and the quality of your work, allowing you to tackle a wide range of projects with ease.

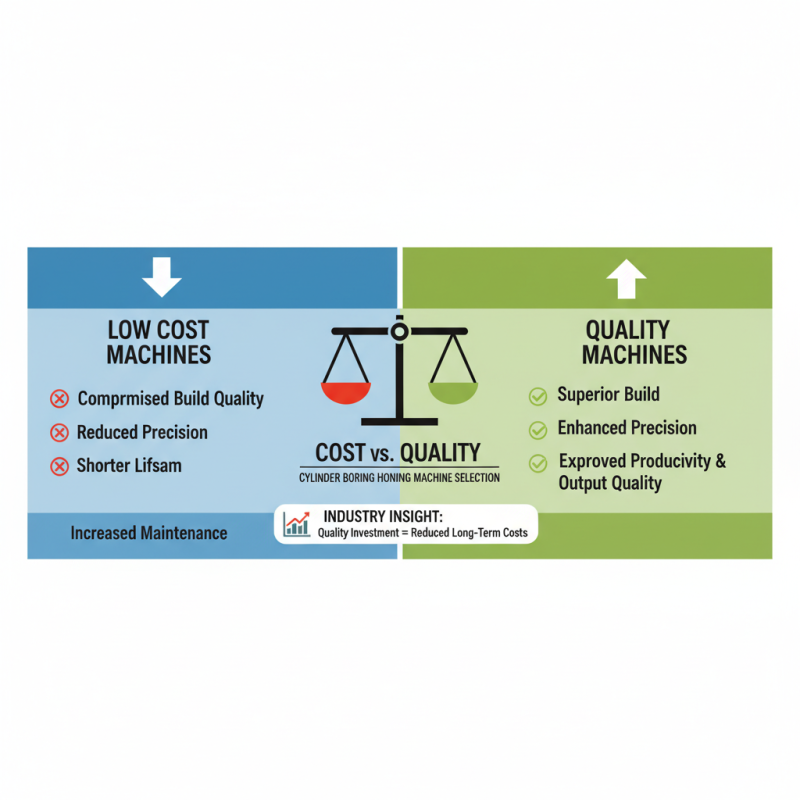

Considering Cost vs. Quality in Machine Selection

When selecting a cylinder boring honing machine, striking the right balance between cost and quality is crucial for maximizing both performance and longevity. Industry reports indicate that machines priced significantly lower than competitors often compromise on build quality, precision, and durability. According to a study by the Machine Tool Manufacturers Association, businesses investing in quality equipment tend to observe a marked increase in productivity, often recouping their investment through reduced maintenance costs and improved output quality.

Tips for making the right choice include conducting thorough market research to compare specifications and user reviews. Understand the unique requirements of your operations—certain jobs may prioritize speed, whereas others may demand high precision. Additionally, consider the total cost of ownership (TCO) beyond the initial price tag; this encompasses maintenance, operation costs, and potential downtime, which can all impact your bottom line significantly. A quality machine, while possibly higher in upfront price, often offers cost savings over time through enhanced efficiency and lower failure rates.

Furthermore, when assessing options, it’s essential to evaluate the level of customer support and availability of replacement parts. Reliable after-sales service can significantly lessen long-term costs related to repairs and replacements. Make sure to network within your industry to gather insights from peers regarding their experiences, as firsthand knowledge can be invaluable in guiding your decision-making process.

Maintenance and Support: Ensuring Longevity of Your Investment

When investing in a cylinder boring honing machine, proper maintenance and support are crucial to ensure the longevity of your equipment. Regular maintenance routines can significantly enhance the machine's efficiency and performance. This includes routine inspections to check for wear and tear, lubrication of moving parts to minimize friction, and the timely replacement of worn components. By adhering to a structured maintenance schedule, operators can prevent costly repairs and downtime, ultimately extending the operational lifespan of their machines.

Additionally, having access to reliable support services is indispensable. Manufacturers or suppliers should provide comprehensive technical support and training to ensure that operators are well-versed in the machine's functionalities and maintenance requirements. Establishing a relationship with support teams can aid in quick troubleshooting and resolution of any issues that arise during operation. Furthermore, investing in compatible spare parts and accessories from reputable sources is vital; this helps maintain the machine's integrity and performance, fostering confidence in the long-term viability of your investment.

Essential Tips for Choosing the Right Cylinder Boring Honing Machine - Maintenance and Support: Ensuring Longevity of Your Investment

| Feature | Importance | Maintenance Tips | Support Options |

|---|---|---|---|

| Machine Durability | High - Influences performance and lifespan | Regular cleaning and inspections | Extended warranty programs |

| Precision Engineering | High - Ensures accuracy in boring and honing | Calibrate machines annually | On-site technical support |

| Ease of Operation | Medium - Affects operator efficiency | Training for operators | User manuals and online resources |

| Spare Parts Availability | High - Reduces downtime | Create a parts inventory | Rapid response service |

| User Reviews and Feedback | Medium - Provides insight into performance | Monitor and address feedback | Customer service hotlines |