Ultimate Guide to Surface Grinding Machines Benefits Tips and Applications

In the realm of precision manufacturing and engineering, the Surface Grinding Machine stands as a pivotal tool that enhances the quality and accuracy of various materials. This sophisticated machine is designed to produce a flat surface by removing material from a workpiece, ensuring that the final product meets exact specifications. The versatility and efficiency of surface grinding machines make them indispensable in a multitude of industries, from aerospace to automotive, enabling manufacturers to achieve high precision and improved surface finishes.

Understanding the benefits and applications of surface grinding machines is essential for professionals seeking to optimize their manufacturing processes. With the right guidance and tips, users can maximize the capabilities of these machines, ensuring that they not only meet production demands but also exceed quality expectations. This ultimate guide will delve into the fundamental aspects of surface grinding machines, exploring their advantages, operational techniques, and suitable applications, providing a comprehensive resource for both newcomers and seasoned operators alike. By leveraging this knowledge, manufacturers can enhance their operational efficiency and maintain a competitive edge in the ever-evolving marketplace.

What is Surface Grinding and How Does It Work?

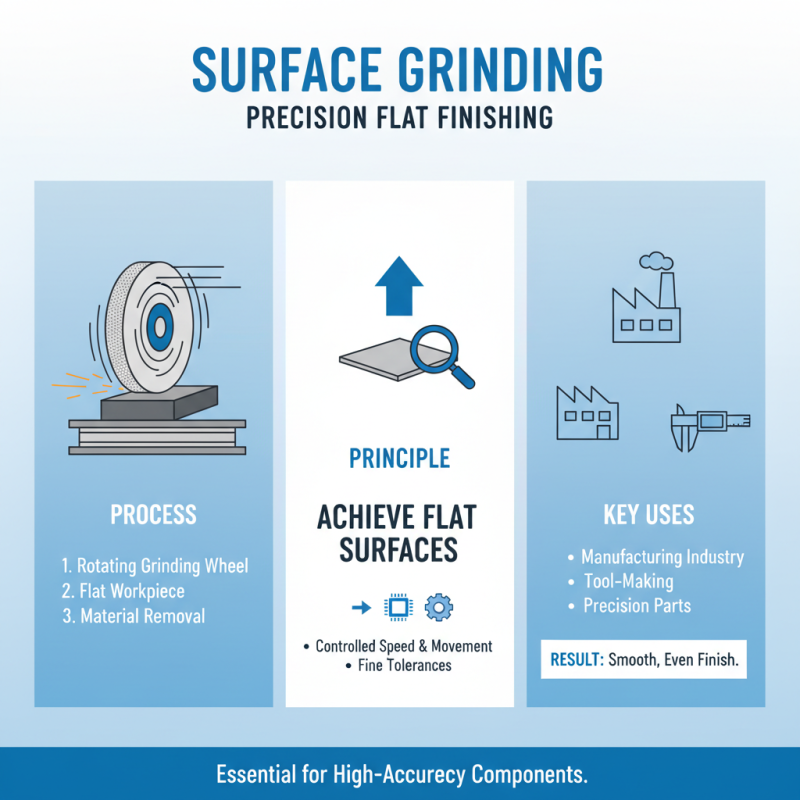

Surface grinding is a precise machining process that utilizes a flat rotating wheel, called a grinding wheel, to achieve a smooth and even finish on the workpiece. This technique is primarily used for creating flat surfaces, and it operates on the principle of removing material from the surface of a metal or other hard material. By controlling the speed and movement of the grinding wheel and the workpiece, operators can attain a high degree of accuracy and fine tolerances, making this method essential in manufacturing and tool-making industries.

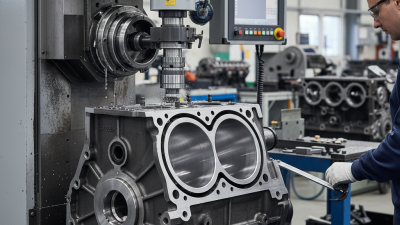

The process begins with the workpiece being securely mounted on a table that can move vertically and horizontally. As the grinding wheel rotates at a high speed, it makes contact with the surface of the workpiece, gradually grinding it down to the desired thickness and finish. The grinding wheel typically consists of abrasive particles, which wear down over time, necessitating regular inspection and replacement to maintain efficiency. Surface grinding is favored for its ability to produce flat and parallel surfaces, making it ideal for applications such as restoring flatness in parts and achieving the necessary finish for subsequent processes in fabrication or assembly.

Key Benefits of Using Surface Grinding Machines

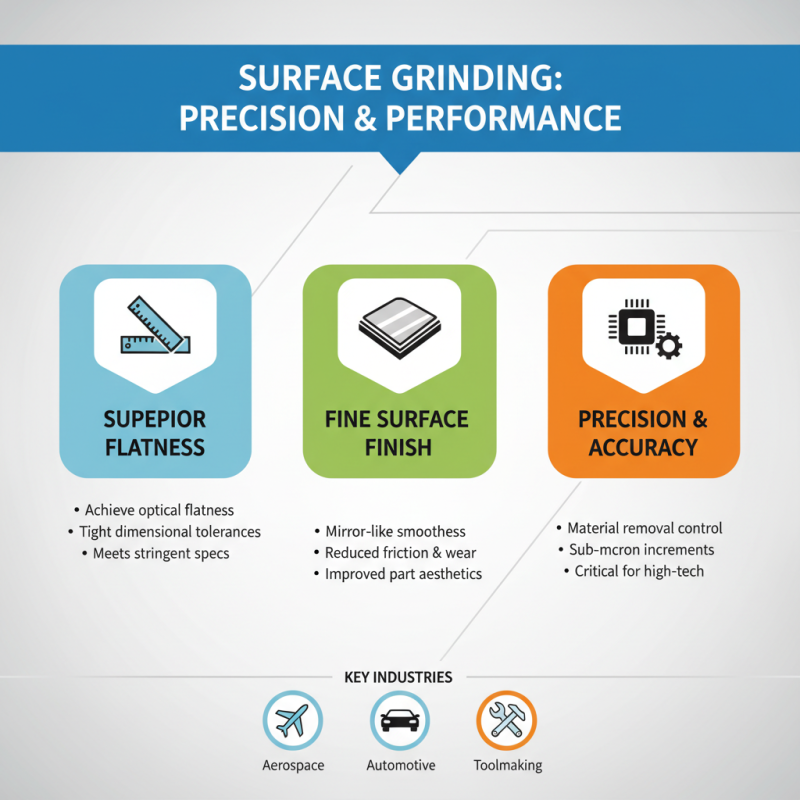

Surface grinding machines offer significant advantages that enhance precision machining processes. One of the primary benefits is their ability to deliver exceptional flatness and surface finish on a wide range of materials. The meticulous grinding process removes small increments of material, achieving tolerances that are often hard to reach with other methods. This results in components that meet stringent dimensional specifications, making these machines invaluable in industries such as aerospace, automotive, and toolmaking.

Another notable advantage is the versatility of surface grinding machines. They can be adapted to process various shapes and sizes, from large plates to intricate components. By utilizing different types of grinding wheels and techniques, operators can achieve the desired surface characteristics, whether it be a high gloss finish or a more functional texture. This adaptability not only boosts productivity, allowing for quicker turnarounds, but also supports a broader range of applications, thereby facilitating more extensive manufacturing capabilities within a single workshop.

Essential Tips for Operating Surface Grinding Machines Safely

Operating surface grinding machines requires diligence and attention to safety to prevent accidents and ensure efficient workflow. The first step in safe operation is to always wear appropriate personal protective equipment (PPE), such as safety glasses, hearing protection, and a dust mask. These items protect the operator from flying debris, excessive noise, and harmful particles that may be generated during the grinding process.

Another essential tip is to conduct a thorough inspection of the machine before use. Check for any signs of wear, damage, or loose parts. Ensure that the grinding wheel is properly mounted and free of cracks or chips. A well-maintained machine not only improves performance but also significantly reduces the risk of accidents. Always ensure that the workpiece is securely clamped, and never attempt to hold it by hand during grinding.

Finally, it is crucial to familiarize yourself with the machine’s operating procedures and safety features. Understanding how to use the emergency stop, coolant system, and other controls can be vital in an emergency. Operators should also maintain a clean and organized workspace, as clutter can lead to accidents. Continuous education on best practices and safety tips can create a safer working environment for everyone involved.

Common Applications of Surface Grinding in Various Industries

Surface grinding is a crucial machining process employed in various industries, serving to achieve highly precise and smooth surfaces on metal and non-metal parts. The aerospace sector, for instance, utilizes surface grinding extensively to enhance the performance and efficiency of engine components and landing gear by ensuring that critical surfaces meet stringent tolerance and finish specifications. According to a report by the International Journal of Advanced Manufacturing Technology, surface grinding contributes significantly to reducing weight in aerospace applications, which is essential for improving fuel efficiency.

In the automotive industry, surface grinding plays a vital role in the production of engine blocks and transmission components, ensuring they meet tight dimensional tolerances. The report further indicates that the global automotive grinding machinery market is expected to reach $4.3 billion by 2025, signaling a robust demand for surface grinding capabilities. This method also finds applications in manufacturing critical parts for medical devices, where precision and cleanliness are paramount. The medical device manufacturing industry relies on surface grinding to produce components that are not only precise but also meet regulatory compliance regarding surface integrity and finish.

Furthermore, the tool and die industry benefits from surface grinding by achieving the necessary flatness and finish required for tooling applications. With advancements in diamond and CBN wheel technologies, the efficiency and effectiveness of surface grinding operations have improved, resulting in shorter cycle times and enhanced productivity across various manufacturing settings. The enhanced capabilities of modern surface grinding machines allow manufacturers to meet evolving industry standards while maintaining competitive advantage.

Common Applications of Surface Grinding in Various Industries

Maintenance Best Practices for Surface Grinding Machines

Proper maintenance is crucial for ensuring the longevity and optimal performance of surface grinding machines. Regular inspections should be conducted to check for wear and tear on critical components such as the grinding wheel, spindle bearings, and coolant system. Keeping grinding wheels properly dressed and balanced not only enhances precision but also prevents excessive vibration, which could lead to damage over time. Additionally, operators should perform routine checks on all moving parts, lubricating them as necessary to reduce friction and prevent mechanical failures.

Another important aspect of maintenance is the management of coolant and debris. Effective filtration systems should be in place to keep the coolant clean, which helps to prevent corrosion and maintain the efficiency of the grinding process. The work area should also be kept free of debris to avoid unintended interference during operation. Implementing a regular cleaning schedule will support a safe working environment and improve the machine’s overall reliability. Regular training for operators on best practices and maintenance protocols can further extend the machine's lifespan and enhance production efficiency.

Ultimate Guide to Surface Grinding Machines: Benefits, Tips, and Applications

| Dimension | Description | Benefits | Best Practices |

|---|---|---|---|

| Grinding Wheel | A rotating tool made from abrasive compounds. | High precision surface finish. | Regularly inspect and replace worn wheels. |

| Coolant | Liquid used to cool and lubricate the grinding process. | Prevents overheating and extends tool life. | Use appropriate coolant for the material being ground. |

| Feed Rate | The speed at which the workpiece is fed into the grinding wheel. | Optimizes efficiency and reduces cycle time. | Adjust feed rate based on material and wheel condition. |

| Surface Finish | The final texture of the machined surface. | Improves component fit and function. | Conduct regular tests to ensure quality is maintained. |

| Machine Alignment | Refers to the correct positioning of the machine components. | Ensures accurate grinding and prolongs machine life. | Perform regular checks and calibrations. |