How to Choose the Right Turret Milling Machine X6325 for Your Needs

Choosing the right milling machine is crucial for maximizing productivity and achieving high-quality results in machining operations. According to industry expert John Smith, a seasoned mechanical engineer and consultant, “Selecting the right Turret Milling Machine X6325 is a decision that will greatly influence the efficiency and precision of your projects.” The Turret Milling Machine X6325 stands out in the realm of milling machines due to its versatility and precision capabilities, making it an excellent choice for a variety of applications, from small-scale fabrications to more complex engineering tasks.

When considering the Turret Milling Machine X6325, it's essential to evaluate your specific needs, including the type of materials you’ll be working with and the complexities of your projects. The X6325 features adjustable spindle speeds and feed rates, making it adaptable to various machining tasks. By understanding these capabilities and aligning them with your operational requirements, you can ensure that your investment will yield optimal results and enhance your production efficiency.

In this guide, we will explore critical factors to consider when selecting the Turret Milling Machine X6325, enabling you to make an informed decision that aligns with your machining demands. Whether you are a seasoned professional or a newcomer to the industry, understanding these elements will help you choose the right machine for your needs.

Understanding the Basics of Turret Milling Machines

When selecting a turret milling machine like the X6325, it's essential to grasp the foundational aspects of turret milling technology. Turret milling machines are versatile tools that allow for intricate machining operations. The design features a rotating turret head that enables users to position the cutting tool at different angles, making it suitable for various applications such as drilling, boring, and milling in one setup. A report by the Allied Market Research highlights that the global milling machine market is projected to reach approximately $6.7 billion by 2025, indicating a growing demand for such equipment in various industries.

Understanding the basic components and functionalities of turret milling machines is also critical. These machines typically consist of a base, column, spindle, and table, working in unison to create precise and complex parts. The CNC (Computer Numerical Control) technology has further enhanced the capabilities of turret mills, allowing for superior precision and consistency. According to data from MarketsandMarkets, the CNC machine market alone is expected to grow at a CAGR of 6.8% between 2020 and 2025, reflecting the increasing reliance on advanced machining technologies. Potential users should evaluate their specific needs, such as the materials they’ll be working with and the extent of customization required, to select the most fitting turret milling machine for their production requirements.

Key Features to Look for in the X6325 Model

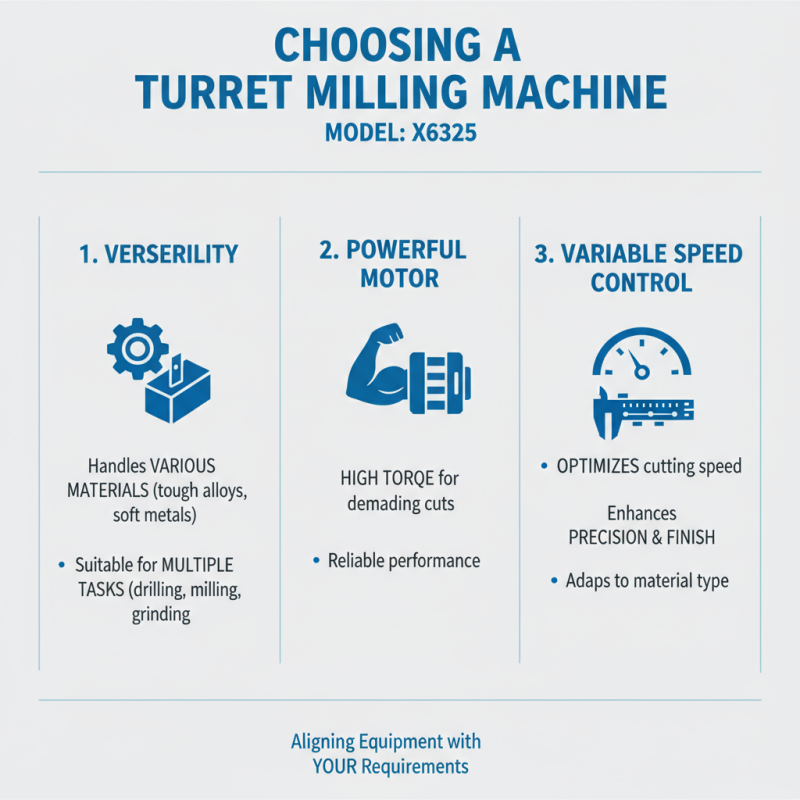

When choosing a turret milling machine like the X6325, several key features are essential to align the equipment with your specific requirements. One of the primary aspects to consider is the machine's versatility in handling various materials and tasks. The X6325 typically comes equipped with a powerful motor that can manage tough alloys and softer materials alike. According to industry reports, machines with variable speed controls allow operators to fine-tune their milling process, optimizing both performance and precision.

Another critical feature is the machine's table size and load capacity. The X6325 usually boasts an ample table that can accommodate larger workpieces while maintaining stability during operation. Data from tool and machinery studies indicate that increased table surface area enhances efficiency by enabling simultaneous setups, reducing downtime significantly. Additionally, a robust construction is vital; a well-built machine experiences less vibration, leading to more accurate cuts.

**Tips:** When evaluating the X6325 model, consider the availability of CNC upgrades. As reported by various manufacturing sources, integrating automation into your milling setup can enhance repetitive task accuracy and reduce manual labor costs. Furthermore, ensure that the machine comes with a comprehensive warranty and reliable customer support, which are indicative of the manufacturer's confidence in their product. Always check user feedback to gain insights into real-world performance and durability of the machine in various operational scenarios.

Assessing Your Project Requirements for the X6325

When assessing project requirements for the X6325 turret milling machine, it’s crucial to consider several key factors that can significantly impact your machining efficiency and product quality. Firstly, evaluate the types of materials you will primarily be working with. According to a report by the International Journal of Advanced Manufacturing Technology, the material's hardness and density can dictate the power and speed specifications of the milling machine you require. For instance, if your projects involve harder metals, you will need a machine that offers higher torque and variable speed options to accommodate these materials effectively.

Another important consideration is the scale and precision of your projects. The X6325 is particularly noted for its versatility in handling various sizes of workpieces; however, it’s essential to match its capabilities with your specific machining dimensions and tolerances. A comprehensive market analysis indicates that machines in the same class as the X6325 typically provide positional accuracy within 0.01 mm. Therefore, if your projects demand high precision for intricate parts, ensuring that the machine’s specifications align with these needs is critical.

Lastly, think about your operation’s productivity requirements. Industry reports have shown that the efficiency of turret milling operations can be enhanced substantially by selecting a machine that integrates easy setup and quick tool changes. This is particularly advantageous for job shops that handle multiple small-run projects. Ensuring that the X6325 meets these operational needs can lead to reduced downtime and increased throughput, directly impacting your overall business performance.

How to Choose the Right Turret Milling Machine X6325 for Your Needs

Comparing X6325 with Other Milling Machines on the Market

When it comes to selecting a turret milling machine, the X6325 model stands out due to its unique features and capabilities that cater to various machining needs. However, understanding how it compares with other milling machines available on the market is essential for making an informed decision. The X6325 offers a robust design that enhances stability during operation, which is crucial for achieving precision in milling. Its versatility in handling different materials makes it an appealing choice for both small-scale workshops and larger manufacturing setups.

In comparison to other milling machines, the X6325 provides superior functionality with its variable speed settings, enabling users to adapt to various machining tasks efficiently. Many competitors may lack the range of speed or the flexibility in milling operations that the X6325 provides, making it a valuable asset for those who require adaptability in their projects. Additionally, while some machines heighten focus on a specific type of milling, the X6325 maintains a balanced approach to multiple milling techniques, ensuring users can complete diverse tasks without needing multiple machines. This comprehensive capability presents a distinct advantage for users looking for an all-in-one solution in their machining arsenal.

How to Choose the Right Turret Milling Machine X6325 for Your Needs

| Feature | X6325 | Milling Machine A | Milling Machine B |

|---|---|---|---|

| Table Size (mm) | 1270 x 250 | 1200 x 300 | 1400 x 260 |

| Spindle Speed (RPM) | 40 - 2000 | 60 - 1800 | 50 - 2500 |

| Power (kW) | 3.0 | 2.2 | 4.0 |

| Weight (kg) | 900 | 800 | 1000 |

| Vertical Travel (mm) | 400 | 350 | 450 |

| Price Range (USD) | $15,000 - $20,000 | $12,000 - $18,000 | $20,000 - $25,000 |

Maintenance Tips for Long-lasting Performance of the X6325

When it comes to ensuring the long-lasting performance of your turret milling machine X6325, regular maintenance is essential. Proper maintenance not only enhances the machine's efficiency but also extends its lifespan, providing you with optimal machining results. One crucial aspect is to regularly clean the machine, removing any debris, chips, and coolant residues that accumulate during operations. A clean machine prevents wear and tear on components, ensuring smooth functionality.

Another important maintenance tip is to regularly check and lubricate all moving parts. Adhering to the manufacturer's lubrication schedule will help maintain the machine's precision and prevent malfunctions. Additionally, it's wise to periodically inspect belts, gears, and bearings for signs of wear. Replacing worn parts promptly can save you from costly repairs in the future.

Finally, calibrating your machine periodically is vital for maintaining accuracy. Routine inspections of the machine's alignment and adjustments as necessary will ensure that it continues to perform at peak levels. Keeping a maintenance log can also help in tracking the performance and schedule of your X6325, making it easier to implement timely interventions as needed.